Search scope:

Years:

6 patents selected (of 288 matches).

Table of Contents

1. US6652967 B2 B32B 20031125 NanoProducts Corporation

Nano-dispersed powders and methods for their manufacture

2. US6652958 B2 B32B 20031125 POLYMATECH CO., LTD.

Thermally conductive polymer sheet

3. US6652923 B2 C23C 20031125 ISE ELECTRONICS CORPORATION

Electron-emitting source, electron-emitting module, and method of manufacturing electron-emitting source

4. US6652148 B2 F16C 20031125 NSK LIMITED

Rolling bearing

5. US6650061 B1 G09G 20031118 SHARP KABUSHIKI KAISHA (SHARP CORPORATION)

Electron-source array and manufacturing method thereof as well as driving method for electron-source array

6. US6649431 B2 H01L 20031118 UT. Battelle, LLC

Carbon tips with expanded bases grown with simultaneous application of carbon source and etchant gases

Abstract: Dispersed powders are disclosed that comprise

fine nanoscale powders dispersed on coarser

carrier powders. The composition of the dispersed

fine powders may be oxides, carbides, nitrides,

borides, chalcogenides, metals, and alloys.

Fine powders discussed are of sizes less

than 100 microns, preferably less than 10

micron, more preferably less than 1 micron,

and most preferably less than 100 nanometers.

Methods for producing such powders in high

volume, low-cost, and reproducible quality

are also outlined. Such powders are useful

in various applications such as catalysts,

sensor, electronic, electrical, photonic,

thermal, biomedical, piezo, magnetic, catalytic

and electrochemical products.

Related Applications: Priority: JP 2000-319844 20001019 Priority: JP 2000/037672 20000216 Related Applications: Priority: JP P 20001019 JP P 20010716 Priority: JP 11-214976 19990729 JP 2000-219621 20000719

2/6 [Back] [Next] [Full/Text] [Full/Image] 検討依頼書

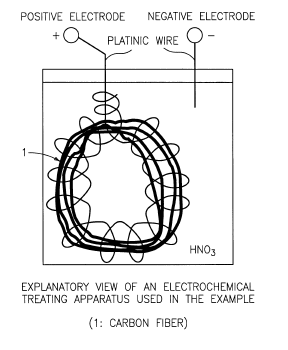

Abstract: A thermally conductive polymer sheet includes

a polymer matrix and graphitized carbon fibers

as a thermally conductive filler. The graphitized

carbon fibers are formed by spinning, infusibilization,

carbonization, pulverized mesophase pitch

before graphitizing the mesophase pitch.

The graphitized carbon fibers have a coating

layer of ferromagnetic material on their

surface. The application of magnetic field

to the coating layer allows the fibers to

be oriented to be perpendicular to the sheet.

Preferably, by X-ray diffractometry, the

graphitized carbon fibers have an interplanar

spacing (d 002 ) of graphite planes of less than 0.3370

nm and a ratio (P 101 /P 100 ) of diffraction peak ( 101 ) to diffraction peak ( 100 ) of at least 1.15. The ferromagnetic material

is preferably at least one of a metal, an

alloy, or a compound selected from the group

consisting of nickel, cobalt and iron.

3/6 [Back] [Next] [Full/Text] [Full/Image] 検討依頼書

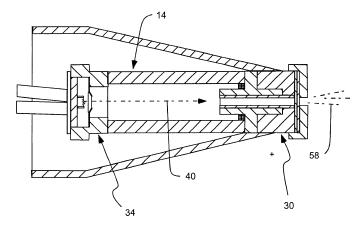

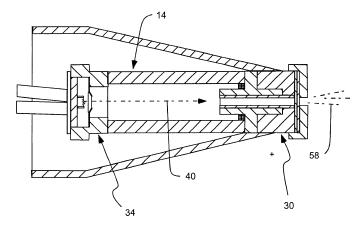

Abstract: An electron-emitting source includes a substrate

and a coating film. The substrate is made

of a material containing a metal serving

as a growth nucleus for nanotube fibers as

a main component, and has a plurality of

through holes. The coating film is constituted

by nanotube fibers formed on a surface of

the substrate and wall surfaces of the through

holes. A method of manufacturing an electron-emitting

source is also disclosed.

4/6 [Back] [Next] [Full/Text] [Full/Image] 検討依頼書

Abstract: A rolling bearing includes a plurality of

rolling elements rotatably retained at substantially

uniform intervals between inner and outer

rings via a retainer, and a grease composition

which contains a conductive substance in

the proportion of 0.1 to 10 wt % and is sealed

in the rolling bearing.

5/6 [Back] [Next] [Full/Text] [Full/Image] 検討依頼書

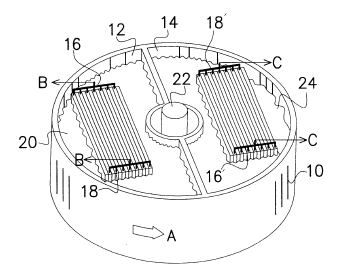

Abstract: The electron-source array of the present

invention is provided with cathode electrodes

placed on an insulation substrate in the

form of lines; and gate electrodes that are

placed face to face with the cathode electrodes

with the insulation film being interpolated

in between. In this arrangement, the cathode

electrodes and the gate electrodes are arranged

so as to intersect each other with a pore

being formed at an intersecting portion between

each cathode electrode and each gate electrode

in a manner so as to penetrate the insulation

film, and the pore is filled with a conductive

material or a semiconductive material with

the material being electrically connected

to the corresponding cathode electrode, and

is formed in a manner so as to separate from

the gate electrodes with a space in between.

Thus, it becomes possible to form very fine

emitters uniformly without the need for a

high-precision patterning technique and consequently

to provide an electron-source array that

enables an X-Y matrix driving process.

6/6 [Back] [Next] [Full/Text] [Full/Image] 検討依頼書

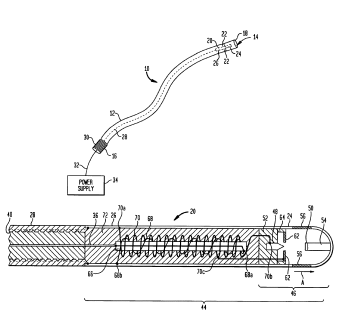

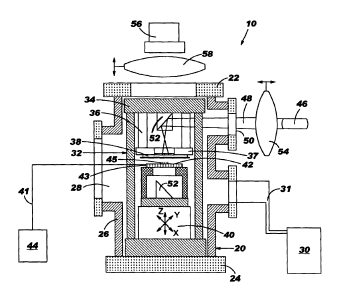

Abstract: Systems and methods are described for carbon

tips with expanded bases. A method includes

producing an expanded based carbon containing

tip including: fabricating a carbon containing

expanded base on a substrate; and then fabricating

a carbon containing fiber on the expanded

base. An apparatus includes a carbon containing

expanded base coupled to a substrate; and

a carbon containing fiber coupled to said

carbon containing expanded base.

--- End of data re-processed by SGshotEx

V8.978 ---